Design a device which would autonomously monitor various electrochemical and physical properties of water, saving the time-stamped readings to an SD MMC card. It could be deployed in ponds, lakes, streams, storm sewers, etc, and would provide data which could later be plotted to reveal changes in the water body's characteristics over time. It would also collect and store samples of water upon detection of peaks in sensor readings. The collected samples could later be analyzed to determine the chemical components responsible for the detected peaks.

I believe information on water quality should be public. In situations where water quality is threatened and monitoring is lacking or data is confidential, I see an opportunity to provide an affordable monitoring device any competent DIYer could build and use. Schematics and program code for this project will be released under GPL license, and priority will be placed on selecting affordable components and construction methods.

Possible sensors:

- conductivity - indication of TDS, Salinity

- temperature

- pH - ~ $50 probe to purchase

- oxidation reduction potential (ORP) - ~ $50 probe to purchase

- turbidity - construct with IR LEDs, photodiodes and housing to shield ambient light

- depth - gut a cheap/used fish-finder or use pressure transducer at known minimum depth

- flow - pitot w/ differential pressure transducer

Circuit:

Microcontroller - PIC 18F4550 - up to 13 analog input channels (for sensors)

Battery pack constructed from commonly available Ni-mh cells or SLA battery

SMPS buck converter running PIC and SD Socket at 3.3V

Software:

Use Microchip's C18 C compiler

Use PetitFat small device Fat file system to read and write data to .txt file on SD card http://elm-chan.org/fsw/ff/00index_p.html

Sampling Hardware:

If I can find a cheap source for pyrex tube, I imagine the sampler could be built like this:

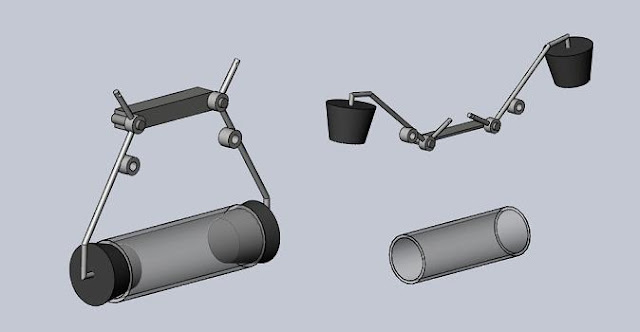

A small gear motor would drive the arms from above, using a crank and rods. A spring joining the arms by their midpoint bushings would maintain constant sealing pressure after the sampler is actuated. Another possibility would be a sampler using two ball bearings valves as pictured below:

When positioned vertically, gravity would hold the ball bearings in place, resting against o-rings and sealing the sample inside. When positioned horizontally, the bearings would separate from the o-rings, allowing flow through the tube. A gear motor could actuate the sampler by pivoting the tube assembly. I'm imagining old computer mouse roller balls would be ideal ball bearings for this application.

This work is licensed under a Creative Commons Attribution 3.0 Unported License.